Hot sale Annealed Bare Copper Conductor – Micro Coaxial Cable Inner Conductor Copper Clad Aluminum Magnesium Wire Used for High-Frequency Signal Transmission – Shenzhou Detail:

Product Detail

To achieve better tensile strength, using aluminum magnesium alloy rod as the core wire, then cladding copper layer on the surface, after drawing several times, then copper clad aluminum magnesium wire is made.

Advantages: Same as CCA Wire, it has low density, easy to solder and high strength.

Disadvantages: As the conductor contains magnesium, the resistivity compared with pure CCA wire is higher. It is not conductive to make conductor for transporting current.

Product Parameter

|

Product name |

CCAM WIRE |

|

Diameters available [mm] Min – Max |

0.05mm-2.00mm |

|

Density [g/cm³] Nom |

2.95-4.00 |

|

Conductivity [S/m * 106] |

31-36 |

|

IACS [%] Nom |

58-65 |

|

Temperature-Coefficient [10-6/K] Min – Max |

3700 – 4200 |

|

Elongation (1)[%] Nom |

17 |

|

Tensile strength (1)[N/mm²] Nom |

170 |

|

Outer metal by volume[%] Nom |

3-22% |

|

Outer metal by weight[%] Nom |

10-52 |

|

Weldability/Solderability[--] |

++/++ |

|

Properties |

CCAM combines the advantages of Aluminum and Copper. Lower density allows weight reduction, elevated conductivity and tensile strength compared to CCA, good weldability and solderability, recommended for very fine sizes down to 0.05mm |

|

Application |

CATV coaxial cable, large capacity communication network signal electric LAN, control signal cable, cable shielding line, metal hose etc. Aspects. |

IEC 60317(GB/T6109)

The Tech & Specification parameters of our company’s wires are in international unit system, with the unit of millimeter (mm). If use American Wire Gauge (AWG) and British Standard Wire Gauge (SWG) , the following table is a comparison table for your reference.

The most special dimension can be customized as per the requirements of customers.

Comparison of Different Metal Conductors’s Tech& Specification

|

METAL |

Copper |

Aluminium Al 99.5 |

CCA10% |

CCA15% |

CCA20% |

CCAM |

TINNED WIRE |

|

Diameters available |

0.04mm -2.50mm |

0.10mm -5.50mm |

0.10mm -5.50mm |

0.10mm -5.50mm |

0.10mm -5.50mm |

0.05mm-2.00mm |

0.04mm -2.50mm |

|

Density [g/cm³] Nom |

8.93 |

2.70 |

3.30 |

3.63 |

3.96 |

2.95-4.00 |

8.93 |

|

Conductivity[S/m * 106] |

58.5 |

35.85 |

36.46 |

37.37 |

39.64 |

31-36 |

58.5 |

|

IACS[%] Nom |

100 |

62 |

62 |

65 |

69 |

58-65 |

100 |

|

Temperature-Coefficient[10-6/K] Min – Max |

3800 – 4100 |

3800 – 4200 |

3700 – 4200 |

3700 – 4100 |

3700 – 4100 |

3700 – 4200 |

3800 – 4100 |

|

Elongation (1)[%] Nom |

25 |

16 |

14 |

16 |

18 |

17 |

20 |

|

Tensile strength (1)[N/mm²] Nom |

260 |

120 |

140 |

150 |

160 |

170 |

270 |

|

Outer metal by volume[%] Nom |

- |

- |

8-12 |

13-17 |

18-22 |

3-22% |

- |

|

Outer metal by weight[%] Nom |

- |

- |

28-32 |

36-40 |

47-52 |

10-52 |

- |

|

Weldability/Solderability[--] |

++/++ |

+/– |

++/++ |

++/++ |

++/++ |

++/++ |

+++/+++ |

|

Properties |

Very high conductivity, good tensile strength, high elongation, excellent windability, good weldability and solderability |

Very low density allows high weight reduction, fast heat dissipation, low conductivity |

CCA combines the advantages of Aluminum and Copper. Low density allows weight reduction, elevated conductivity and tensile strength compared to Aluminum, good weldability and solderability, recommended for diameter 0.10mm and above |

CCA combines the advantages of Aluminum and Copper. Lower density allows weight reduction, elevated conductivity and tensile strength compared to Aluminum, good weldability and solderability, recommended for very fine sizes down to 0.10mm |

CCA combines the advantages of Aluminum and Copper. Lower density allows weight reduction, elevated conductivity and tensile strength compared to Aluminum, good weldability and solderability, recommended for very fine sizes down to 0.10mm |

CCAM combines the advantages of Aluminum and Copper. Lower density allows weight reduction, elevated conductivity and tensile strength compared to CCA, good weldability and solderability, recommended for very fine sizes down to 0.05mm |

Very high conductivity, good tensile strength, high elongation, excellent windability, good weldability and solderability |

|

Application |

General coil winding for electrical application, HF litz wire. For use in industrial, automotive, appliance, consumer electronics |

Different electrical application with low weight requirement, HF litz wire. For use in industrial, automotive, appliance, consumer electronics |

Loudspeaker, headphone and earphone, HDD, induction heating with the need of good termination |

Loudspeaker, headphone and earphone, HDD, induction heating with the need of good termination, HF litz wire |

Loudspeaker, headphone and earphone, HDD, induction heating with the need of good termination, HF litz wire |

Electrical wire and cable, HF litz wire |

Electrical wire and cable, HF litz wire |

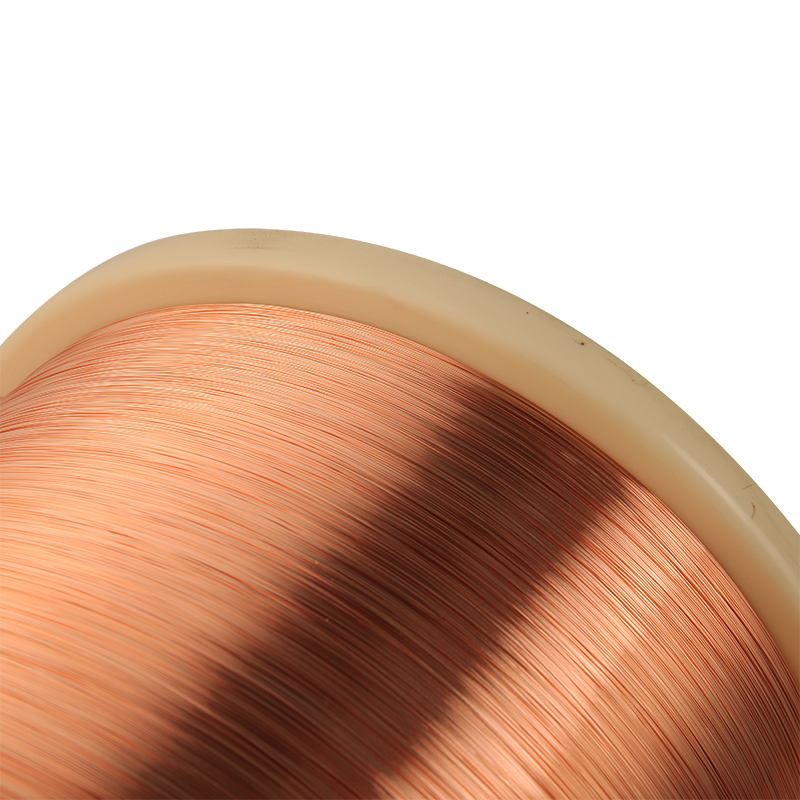

Product detail pictures:

Related Product Guide:

We insist about the theory of growth of 'High excellent, Performance, Sincerity and Down-to-earth working approach' to offer you with great company of processing for Hot sale Annealed Bare Copper Conductor – Micro Coaxial Cable Inner Conductor Copper Clad Aluminum Magnesium Wire Used for High-Frequency Signal Transmission – Shenzhou , The product will supply to all over the world, such as: Detroit, Uruguay, Malta, We warmly welcome your patronage and will serve our clients both at home and abroad with products and solutions of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.