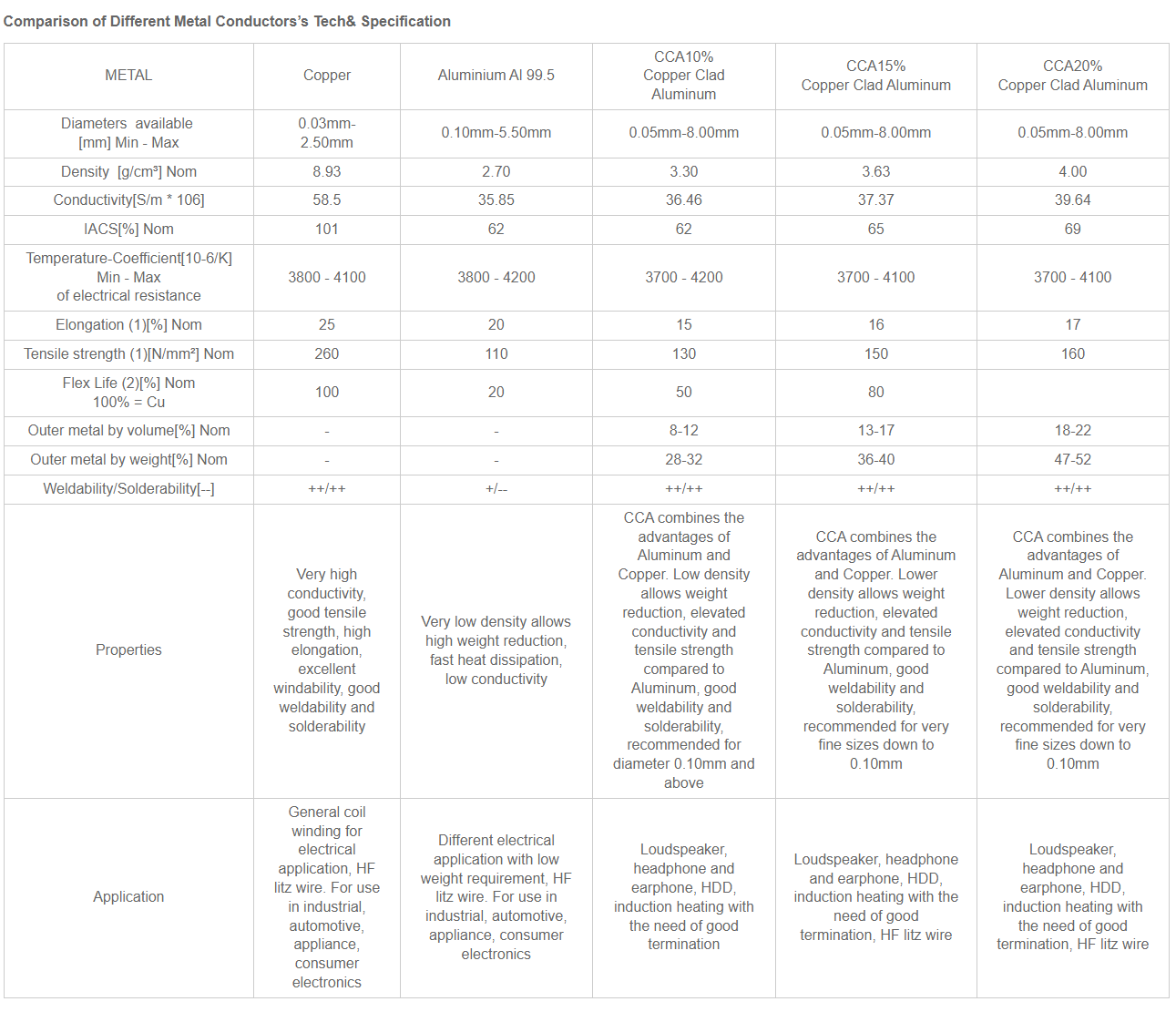

Fast delivery Enameled Copper - Best selling enameled copper clad aluminum wire for eleltromagnetic coil motors – Shenzhou Detail:

Model Introduction

|

Model introduction |

||||||||

|

Product Type |

PEW/130 |

PEW/155 |

UEW/130 |

UEW/155 |

UEW/180 |

EIW/180 |

EI/AIW/200 |

EI/AIW/220 |

|

General Description |

130Grade Polyester |

155Grade Modified Polyester |

155Grade Solderability Polyurethane |

155Grade Solderability Polyurethane |

180Grade Straight Welded Polyurethane |

180Grade Polyester Imine |

200Grade Polyamide imide compound polyester imide |

220Grade Polyamide imide compound polyester imide |

|

IEC Guideline |

IEC60317-3 |

IEC60317-3 |

IEC 60317-20, IEC 60317-4 |

IEC 60317-20, IEC 60317-4 |

IEC 60317-51,IEC 60317-20 |

IEC 60317-23, IEC 60317-3, IEC 60317-8 |

IEC60317-13 |

IEC60317-26 |

|

NEMA Guideline |

NEMA MW 5-C |

NEMA MW 5-C |

MW 75C |

MW 79, MW 2, MW 75 |

MW 82, MW79, MW75 |

MW 77, MW 5, MW 26 |

NEMA MW 35-C |

NEMA MW 81-C |

|

UL-Approval |

/ |

YES |

YES |

YES |

YES |

YES |

YES |

YES |

|

Diameters Available |

0.03mm-4.00mm |

0.03mm-4.00mm |

0.03mm-4.00mm |

0.03mm-4.00mm |

0.03mm-4.00mm |

0.03mm-4.00mm |

0.03mm-4.00mm |

0.03mm-4.00mm |

|

Temperature Index (°C ) |

130 |

155 |

155 |

155 |

180 |

180 |

200 |

220 |

|

Softening Breakdown Temperature(°C) |

240 |

270 |

200 |

200 |

230 |

300 |

320 |

350 |

|

Thermal Shock Temperature(°C) |

155 |

175 |

175 |

175 |

200 |

200 |

220 |

240 |

|

Solderability |

Not weldable |

Not weldable |

380℃/2s Solderable |

380℃/2s Solderable |

390℃/3s Solderable |

Not weldable |

Not weldable |

Not weldable |

|

Characteristics |

Good heat resistance and mechanical strength. |

Excellent chemical resistance; good scratch resistance; poor hydrolysis resistance |

Softening breakdown temperature is higher than UEW/130; easy to dye; low dielectric loss at high frequency; no salt water pinhole |

Softening breakdown temperature is higher than UEW/130; easy to dye; low dielectric loss at high frequency; no salt water pinhole |

Softening breakdown temperature is higher than UEW/155; straight soldering temperature is 390 °C; easy to dye; low dielectric loss at high frequency; no salt water pinhole |

High heat resistance; excellent chemical resistance, high heat shock, high softening breakdown |

High heat resistance; thermal stability; cold-resistant refrigerant; high softening breakdown; high thermal shock |

High heat resistance; thermal stability; cold-resistant refrigerant; high softening breakdown; high heat rush |

|

Application |

Ordinary motor, medium transformer |

Ordinary motor, medium transformer |

Relays, micro-motors, small transformers, ignition coils, water stop valves, magnetic heads, coils for communication equipment. |

Relays, micro-motors, small transformers, ignition coils, water stop valves, magnetic heads, coils for communication equipment. |

Relays, micro-motors, small transformers, ignition coils, water stop valves, magnetic heads, coils for communication equipment. |

Oil-immersed transformer, small motor, high-power motor, high-temperature transformer, heat-resistant component |

Oil-immersed transformer, high-power motor, high-temperature transformer, heat-resistant component, sealed motor |

Oil-immersed transformer, high-power motor, high-temperature transformer, heat-resistant component, sealed motor |

IEC 60317(GB/T6109)

The Tech & Specification parameters of our company’s wires are in international unit system, with the unit of millimeter (mm). If use American Wire Gauge (AWG) and British Standard Wire Gauge (SWG) , the following table is a comparison table for your reference.

The most special dimension can be customized as per the requirements of customers.

Enameled Copper Clad Aluminum Wire Specification

|

Nominal diameter |

Conductor tolerance |

G1 |

G2 |

Minimum breakdown voltage(V) |

Minimum elongation |

|||

|

Minimum film thickness |

Complete Maximum outer diameter(mm) |

Minimum film thickness |

Complete Maximum outer diameter(mm) |

G1 |

G2 |

|||

|

0.10 |

0.003 |

0.005 |

0.115 |

0.009 |

0.124 |

1200 |

2200 |

11 |

|

0.12 |

0.003 |

0.006 |

0.137 |

0.01 |

0.146 |

1600 |

2900 |

11 |

|

0.15 |

0.003 |

0.0065 |

0.17 |

0.0115 |

0.181 |

1800 |

3200 |

15 |

|

0.17 |

0.003 |

0.007 |

0.193 |

0.0125 |

0.204 |

1800 |

3300 |

15 |

|

0.19 |

0.003 |

0.008 |

0.215 |

0.0135 |

0.227 |

1900 |

3500 |

15 |

|

0.2 |

0.003 |

0.008 |

0.225 |

0.0135 |

0.238 |

2000 |

3600 |

15 |

|

0.21 |

0.003 |

0.008 |

0.237 |

0.014 |

0.25 |

2000 |

3700 |

15 |

|

0.23 |

0.003 |

0.009 |

0.257 |

0.016 |

0.271 |

2100 |

3800 |

15 |

|

0.25 |

0.004 |

0.009 |

0.28 |

0.016 |

0.296 |

2300 |

4000 |

15 |

|

0.27 |

0.004 |

0.009 |

0.3 |

0.0165 |

0.318 |

2300 |

4000 |

15 |

|

0.28 |

0.004 |

0.009 |

0.31 |

0.0165 |

0.328 |

2400 |

4100 |

15 |

|

0.30 |

0.004 |

0.01 |

0.332 |

0.0175 |

0.35 |

2400 |

4100 |

16 |

|

0.32 |

0.004 |

0.01 |

0.355 |

0.0185 |

0.371 |

2400 |

4200 |

16 |

|

0.33 |

0.004 |

0.01 |

0.365 |

0.019 |

0.381 |

2500 |

4300 |

16 |

|

0.35 |

0.004 |

0.01 |

0.385 |

0.019 |

0.401 |

2600 |

4400 |

16 |

|

0.37 |

0.004 |

0.011 |

0.407 |

0.02 |

0.425 |

2600 |

4400 |

17 |

|

0.38 |

0.004 |

0.011 |

0.417 |

0.02 |

0.435 |

2700 |

4400 |

17 |

|

0.40 |

0.005 |

0.0115 |

0.437 |

0.02 |

0.455 |

2800 |

4500 |

17 |

|

0.45 |

0.005 |

0.0115 |

0.488 |

0.021 |

0.507 |

2800 |

4500 |

17 |

|

0.50 |

0.005 |

0.0125 |

0.54 |

0.0225 |

0.559 |

3000 |

4600 |

19 |

|

0.55 |

0.005 |

0.0125 |

0.59 |

0.0235 |

0.617 |

3000 |

4700 |

19 |

|

0.57 |

0.005 |

0.013 |

0.61 |

0.024 |

0.637 |

3000 |

4800 |

19 |

|

0.60 |

0.006 |

0.0135 |

0.642 |

0.025 |

0.669 |

3100 |

4900 |

20 |

|

0.65 |

0.006 |

0.014 |

0.692 |

0.0265 |

0.723 |

3100 |

4900 |

20 |

|

0.70 |

0.007 |

0.015 |

0.745 |

0.0265 |

0.775 |

3100 |

5000 |

20 |

|

0.75 |

0.007 |

0.015 |

0.796 |

0.028 |

0.829 |

3100 |

5000 |

20 |

|

0.80 |

0.008 |

0.015 |

0.849 |

0.03 |

0.881 |

3200 |

5000 |

20 |

|

0.85 |

0.008 |

0.016 |

0.902 |

0.03 |

0.933 |

3200 |

5100 |

20 |

|

0.90 |

0.009 |

0.016 |

0.954 |

0.03 |

0.985 |

3300 |

5200 |

20 |

|

0.95 |

0.009 |

0.017 |

1.006 |

0.0315 |

1.037 |

3400 |

5200 |

20 |

|

1.0 |

0.01 |

0.0175 |

1.06 |

0.0315 |

1.094 |

3500 |

5200 |

20 |

|

1.05 |

0.01 |

0.0175 |

1.111 |

0.032 |

1.145 |

3500 |

5200 |

20 |

|

1.1 |

0.01 |

0.0175 |

1.162 |

0.0325 |

1.196 |

3500 |

5200 |

20 |

|

1.2 |

0.012 |

0.0175 |

1.264 |

0.0335 |

1.298 |

3500 |

5200 |

20 |

|

1.3 |

0.012 |

0.018 |

1.365 |

0.034 |

1.4 |

3500 |

5200 |

20 |

|

1.4 |

0.015 |

0.018 |

1.465 |

0.0345 |

1.5 |

3500 |

5200 |

20 |

|

1.48 |

0.015 |

0.019 |

1.546 |

0.0355 |

1.585 |

3500 |

5200 |

20 |

|

1.5 |

0.015 |

0.019 |

1.566 |

0.0355 |

1.605 |

3500 |

5200 |

20 |

|

1.6 |

0.015 |

0.019 |

1.666 |

0.0355 |

1.705 |

3500 |

5200 |

20 |

|

1.7 |

0.018 |

0.02 |

1.768 |

0.0365 |

1.808 |

3500 |

5200 |

20 |

|

1.8 |

0.018 |

0.02 |

1.868 |

0.0365 |

1.908 |

3500 |

5200 |

20 |

|

1.9 |

0.018 |

0.021 |

1.97 |

0.0375 |

2.011 |

3500 |

5200 |

20 |

|

2.0 |

0.02 |

0.021 |

2.07 |

0.04 |

2.113 |

3500 |

5200 |

20 |

|

2.5 |

0.025 |

0.0225 |

2.575 |

0.0425 |

2.62 |

3500 |

5200 |

20 |

Comparison of safety tension of wire winding operation (enameled round copper clad aluminum wires)

|

Conductor diameter (mm) |

Tension (g) |

Conductor diameter (mm) |

Tension (g) |

|

0.1 |

49 |

0.45 |

501 |

|

0.11 |

59 |

0.47 |

497 |

|

0.12 |

70 |

0.50 |

563 |

|

0.13 |

79 |

0.51 |

616 |

|

0.14 |

85 |

0.52 |

608 |

|

0.15 |

97 |

0.53 |

632 |

|

0.16 |

111 |

0.55 |

545 |

|

0.17 |

125 |

0.60 |

648 |

|

0.18 |

125 |

0.65 |

761 |

|

0.19 |

139 |

0.70 |

882 |

|

0.2 |

136 |

0.75 |

1013 |

|

0.21 |

150 |

0.80 |

1152 |

|

0.22 |

157 |

0.85 |

1301 |

|

0.23 |

172 |

0.90 |

1458 |

|

0.24 |

187 |

0.95 |

1421 |

|

0.25 |

203 |

1.00 |

1575 |

|

0.26 |

220 |

1.05 |

1736 |

|

0.27 |

237 |

1.10 |

1906 |

|

0.28 |

255 |

1.15 |

2083 |

|

0.29 |

273 |

1.20 |

2268 |

|

0.3 |

251 |

1.25 |

2461 |

|

0.32 |

286 |

1.30 |

2662 |

Note: Always use all the best safety practices and pay attention to the safety guidelines of the winder or other equipment manufactur

Precautions for use USAGE NOTICE

1. Please refer to the product introduction to select the appropriate product model and specification to avoid the failure to use due to the inconsistent characteristics.

2. When receiving the goods, confirm the weight and whether the outer packing box is crushed, damaged, dented or deformed; In the process of handling, it should be handled with care to avoid vibration to make the cable fall down as a whole, resulting in no thread head, stuck wire and no smooth setting out.

3. During storage, pay attention to protection, prevent from being bruised and crushed by metal and other hard objects, and prohibit mixed storage with organic solvent, strong acid or alkali. The unused products should be wrapped tightly and stored in the original package.

4. The enameled wire should be stored in a ventilated warehouse away from dust (including metal dust). Direct sunlight is prohibited to avoid high temperature and humidity. The best storage environment is: temperature ≤50 ℃ and relative humidity ≤ 70%.

5. When removing the enameled spool, hook the right index finger and middle finger to the upper end plate hole of the reel, and hold the lower end plate with the left hand. Do not touch the enameled wire directly with your hand.

6. During the winding process, the spool should be put into the pay off cover as far as possible to avoid wire damage or solvent pollution; In the process of paying off, the winding tension should be adjusted according to the safety tension table, so as to avoid wire breakage or wire elongation caused by excessive tension, and at the same time, avoid wire contact with hard objects, resulting in paint film damage and poor short circuit.

7. Pay attention to the concentration and amount of solvent (methanol and anhydrous ethanol are recommended) when bonding the solvent bonded self-adhesive line, and pay attention to the adjustment of the distance between the hot air pipe and the mold and the temperature when bonding the hot melt bonded self-adhesive line.

Product detail pictures:

Related Product Guide:

With our loaded working experience and thoughtful products and services, we've got been acknowledged as a reputable supplier for most international buyers for Fast delivery Enameled Copper - Best selling enameled copper clad aluminum wire for eleltromagnetic coil motors – Shenzhou , The product will supply to all over the world, such as: Jamaica, Amman, Rio de Janeiro, we have 8 years experience of production and 5 years experience in trading with the customers all over the world. our clients mainly distributed in the North America, Africa and Eastern Europe. we can supply high quality products with the very competitive price.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!