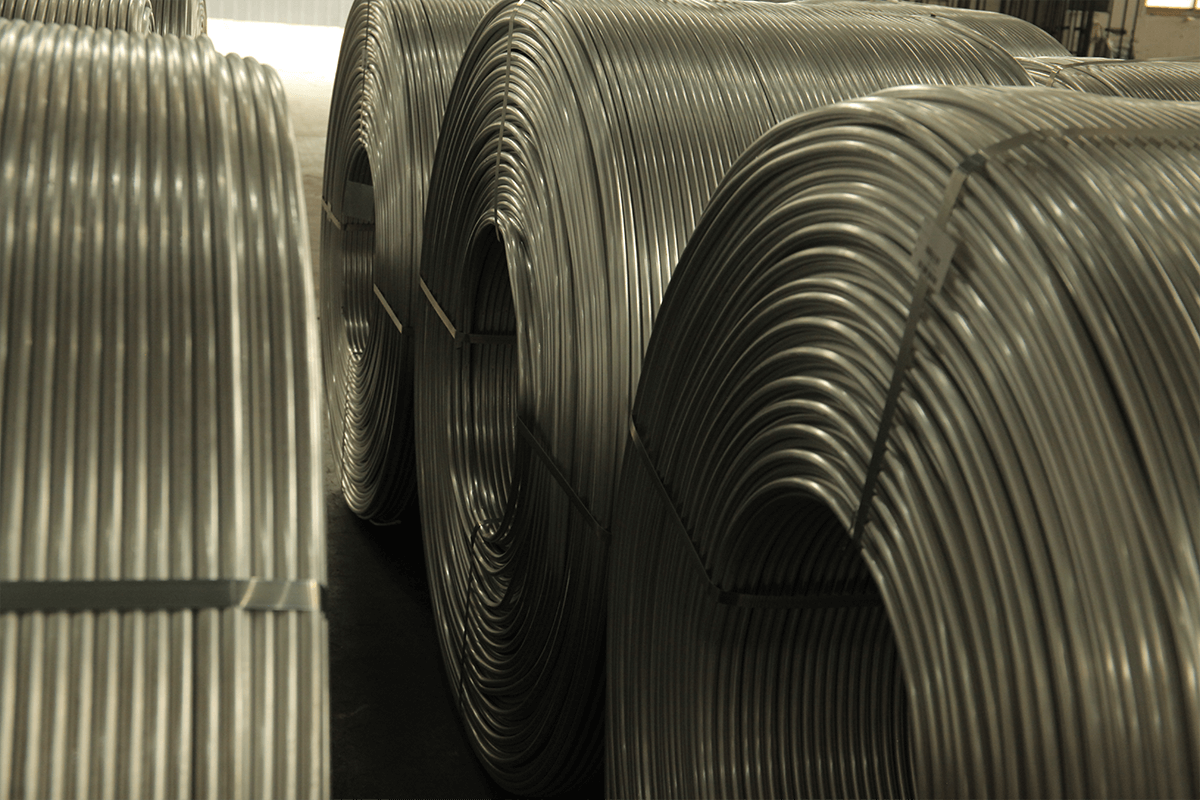

CCA Wire Raw Material: Copper layer Aluminum Wire

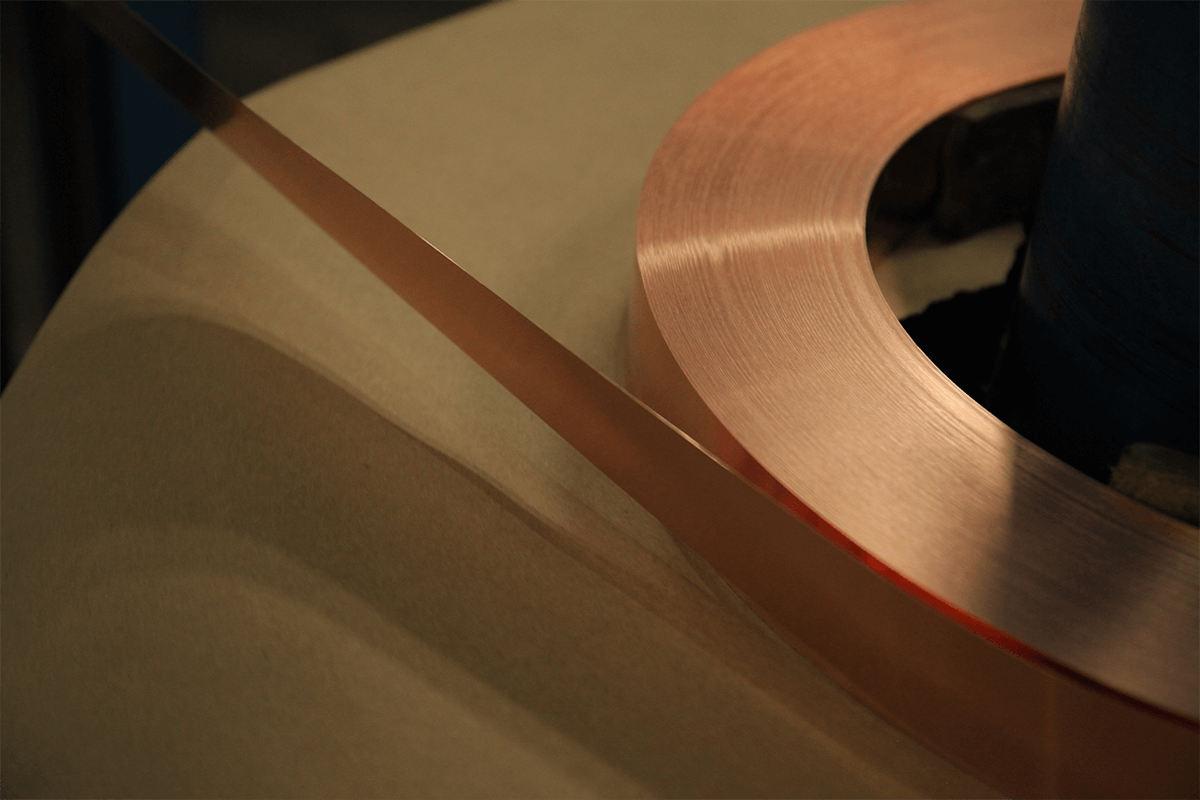

Clading process: By argon arc welding, the fine copper layer will clad on aluminum rod

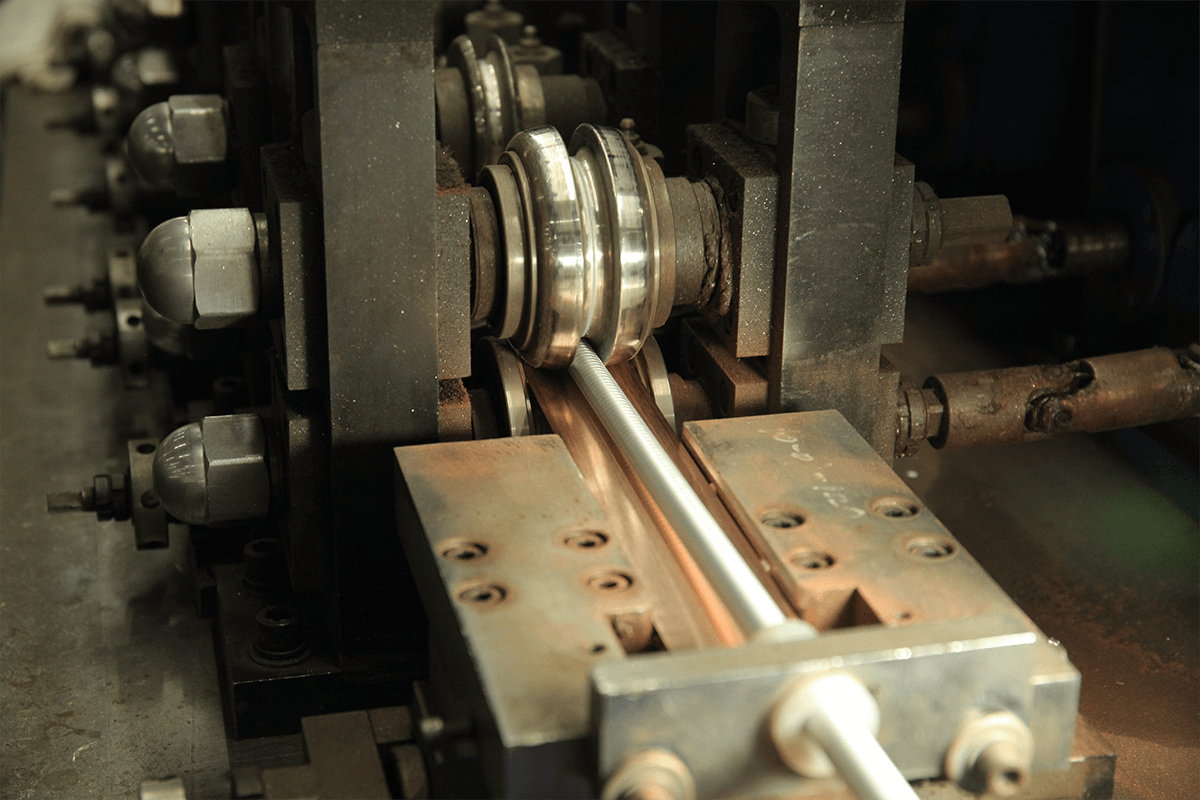

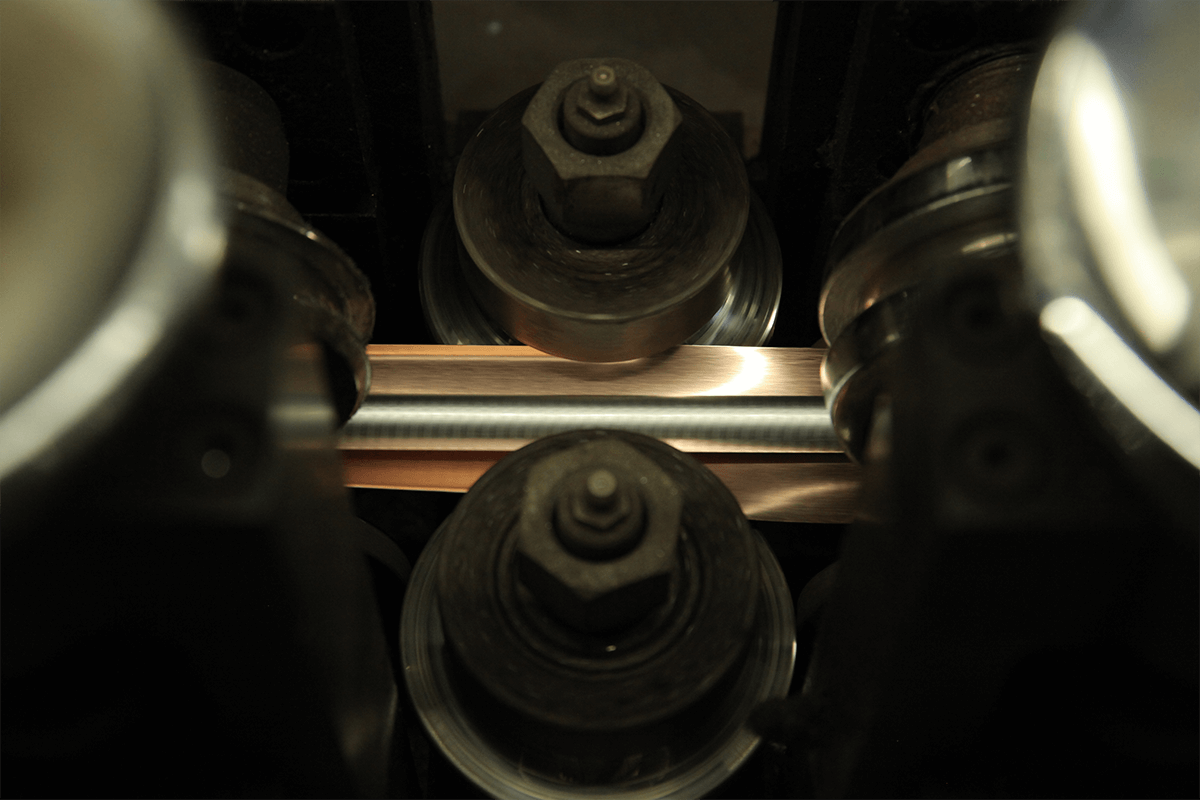

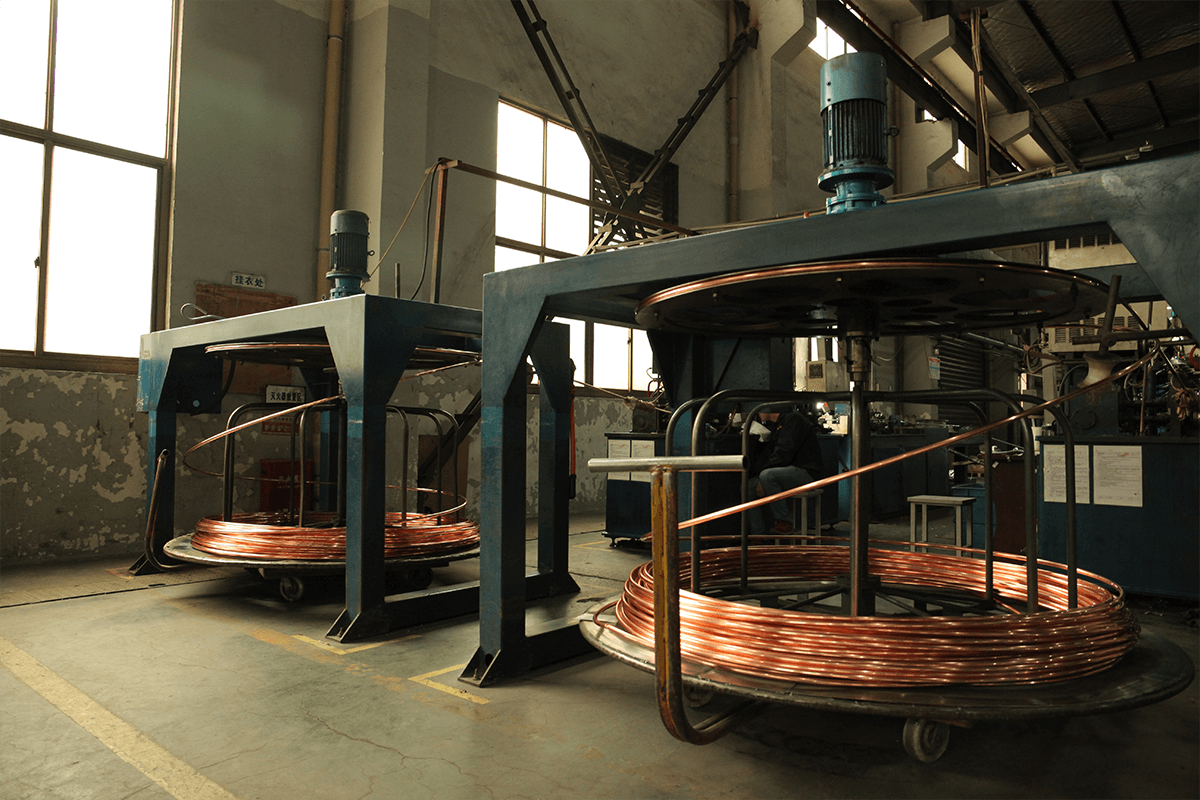

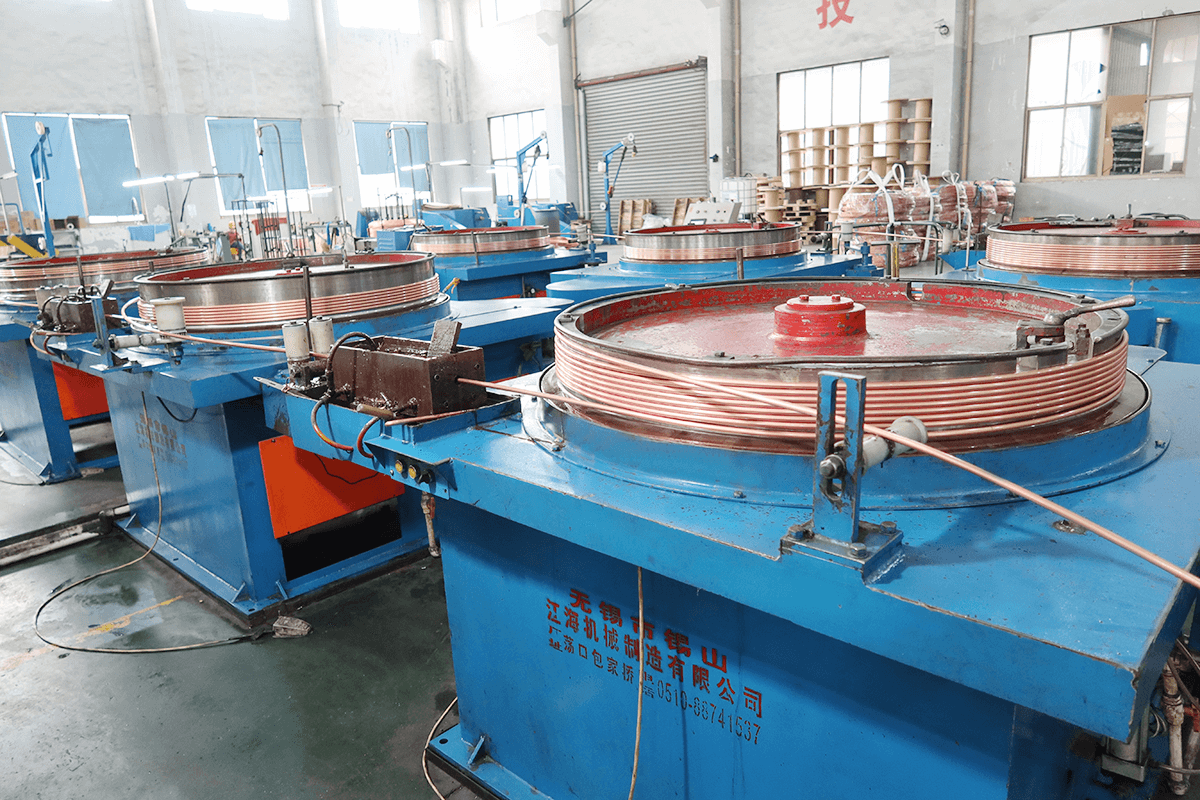

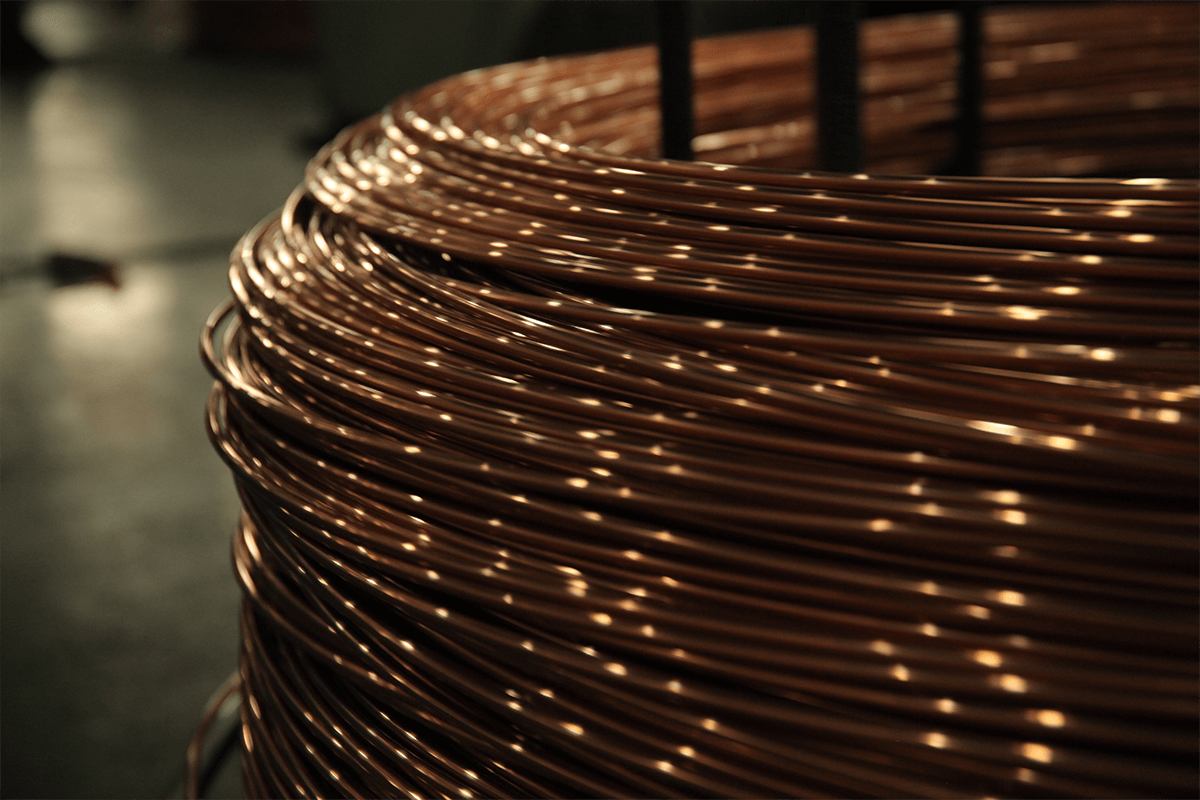

through multi-channel mold, draw big size of copper clad aluminum wire to the required specifications. Middle drawing: draw big size wire to medium size( 0.60-3.00mm); Small drawing: draw medium size to even smaller size, for the enamelling process using.

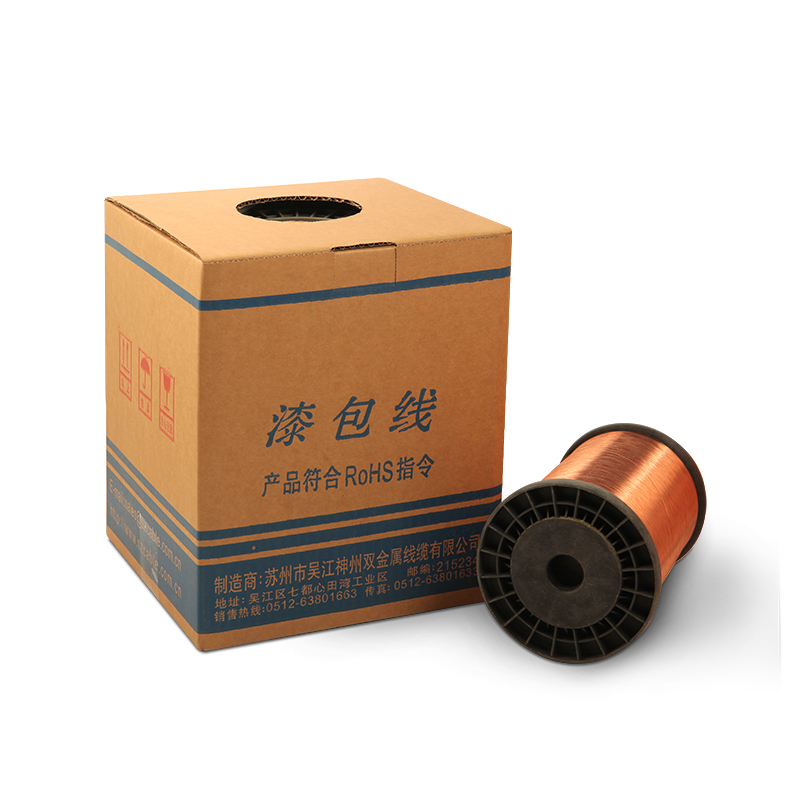

The specified wire finished in drawing workshop, go through annealing and enameling process, then winding on required spools.

● Quality inspection tester

● Company technical strength

● Photos of testing equipment

Peel twist teste

High voltage breakdown tester

Dielectric loss system

The enameled layer continuity tester

High temperature voltage breakdown tester

Intelligent resistance tester

● Enameled wire online monitoring system

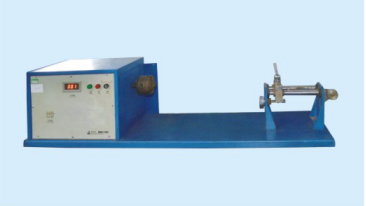

● The springback angle tester

● Elongation tester

● Static friction tester

● Quick snapping tester

● Reciprocating scraping paint tester

● Soldering tester