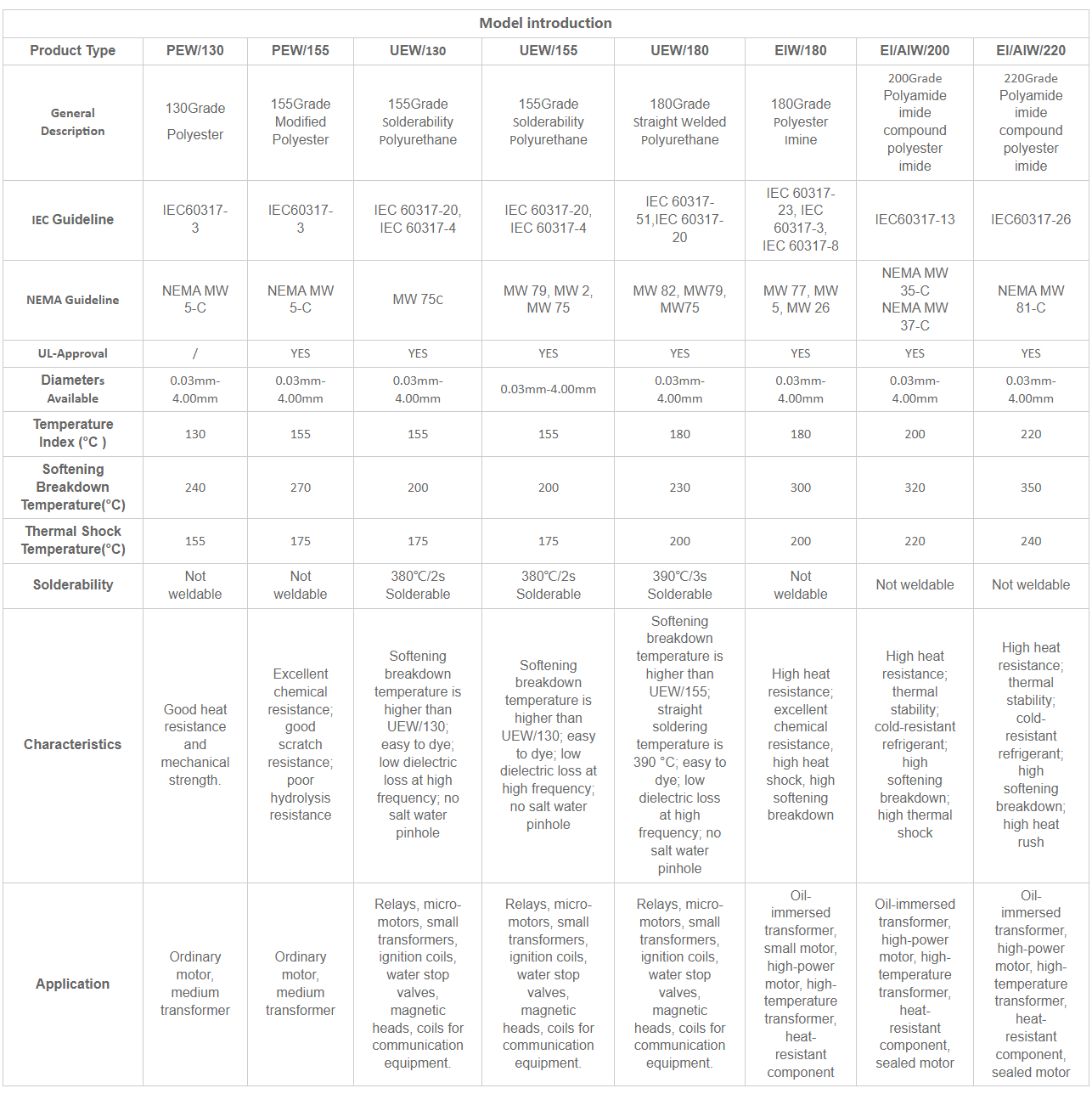

Isingeniso esiyisibonelo

Imininingwane Yomkhiqizo

I-IEC 60317(GB/T6109)

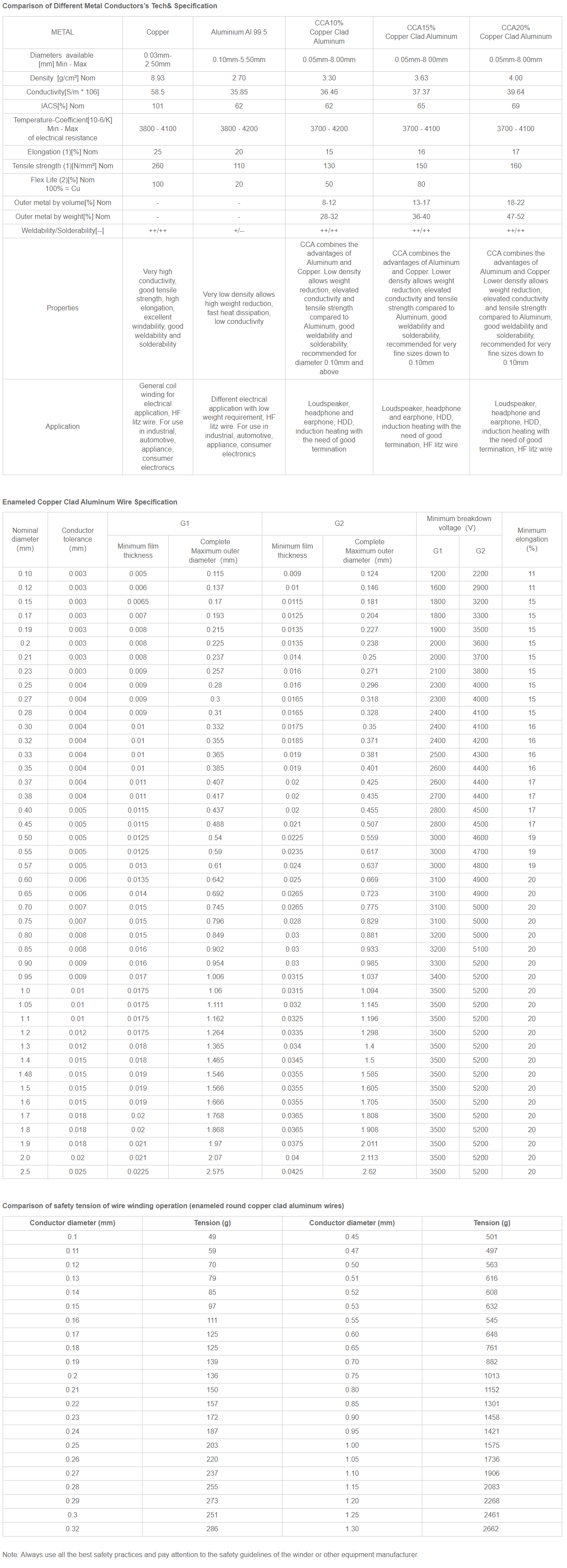

Imingcele ye-Tech & Specification yezintambo zenkampani yethu ikusistimu yeyunithi yamazwe ngamazwe, neyunithi yemilimitha (mm). Uma usebenzisa i-American Wire Gauge (AWG) ne-British Standard Wire Gauge (SWG) , ithebula elilandelayo liyithebula lokuqhathanisa lereferensi yakho.

Ubukhulu obukhethekile kakhulu bungenziwa ngokwezifiso ngokwezidingo zamakhasimende.

Izinyathelo zokuphepha zokusetshenziswa USAGE NOTICE

1. Sicela ubheke isingeniso somkhiqizo ukuze ukhethe imodeli yomkhiqizo efanele kanye nencazelo ukuze ugweme ukwehluleka ukusebenzisa ngenxa yezici ezingahambisani.

2. Lapho uthola izimpahla, qinisekisa isisindo kanye nokuthi ibhokisi lokupakisha langaphandle lichotshoziwe, lilimele, liboshiwe noma likhubazekile; Enqubweni yokuphatha, kufanele iphathwe ngokucophelela ukuze kugwenywe ukudlidliza ukuze ikhebula liwe phansi lilonke, okuholele ekutheni kungabikho khanda lentambo, ucingo olunamathele futhi kungabikho ukusetha okubushelelezi.

3. Ngesikhathi sokugcina, qaphela ukuvikelwa, ugweme ukuthi ungalinyazwa futhi uchotshozwe yinsimbi nezinye izinto eziqinile, futhi uvimbele ukugcinwa okuxubile nge-organic solvent, i-asidi eqinile noma i-alkali. Imikhiqizo engasetshenziswanga kufanele isongwe ngokuqinile futhi igcinwe ephaketheni lokuqala.

4. Intambo enoqweqwe oluqinile kufanele igcinwe endaweni yokugcina impahla ekhipha umoya kude nothuli (kuhlanganise nothuli lwensimbi). Ukukhanya kwelanga okuqondile akuvunyelwe ukugwema izinga lokushisa eliphezulu nomswakama. Indawo engcono kakhulu yokugcina indawo: izinga lokushisa ≤50 ℃ kanye nomswakama ohlobene ≤ 70%.

5. Lapho ukhipha i-spool ene-enameled, hoka umunwe wenkomba ongakwesokudla nomunwe ophakathi nendawo engenhla yepuleti le-reel, bese ubamba i-end plate engezansi ngesandla sobunxele. Ungathinti intambo ene-enameled ngqo ngesandla sakho.

6. Ngesikhathi sokusongwa, i-spool kufanele ifakwe kwikhava yokukhokha ngangokunokwenzeka ukuze kugwenywe ukulimala kocingo noma ukungcoliswa kwezinyibilikisi; Enkambweni yokukhokha, ukungezwani okumazombezombe kufanele kulungiswe ngokuya ngetafula lokuqina lokuphepha, ukuze kugwenywe ukuphuka kwentambo noma ukwelulwa kocingo okubangelwa ukungezwani okukhulu, futhi ngesikhathi esifanayo, gwema ukuthintana kwezintambo nezinto eziqinile, okuholela ekulimaleni kwefilimu kapende kanye nokujikeleza okufushane okumpofu.

7. Naka ukugxila kanye nenani le-solvent (kunconywa i-methanol ne-anhydrous ethanol) lapho uhlanganisa umugqa wokuzinamathisela ohlanganisiwe we-solvent, futhi unake ukulungiswa kwebanga eliphakathi kwepayipi lomoya oshisayo kanye nesikhunta kanye nezinga lokushisa lapho ubopha umugqa wokuzibamba oshisayo oncibilikayo.