Hordhac Model

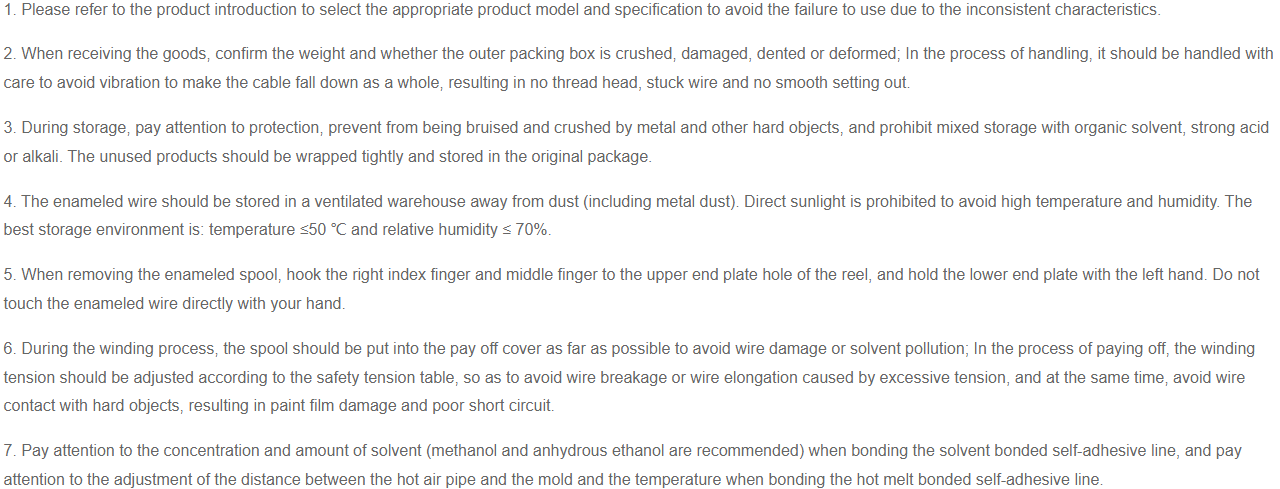

| Hordhac model | ||||||||

| AlaabtaNooca | PEW/130 | PEW/155 | UEW/130 | UEW/155 | UEW/180 | EIW/180 | EI/AIW/200 | EI/AIW/220 |

| Sharaxaada Guud | 130 Fasalka Polyester | 155 Fasalka Polyester-ka La Bedelay | 155 FasalkaSwaayeelnimoPolyurethane | 155 FasalkaSwaayeelnimoPolyurethane | 180 FasalkaStoosanWduqoobayPolyurethane | 180 FasalkaPolyesterItayda | 200 FasalkaPolyamide imide ka kooban polyester imide | 220 FasalkaPolyamide imide ka kooban polyester imide |

| IECTilmaamaha | IEC60317-3 | IEC60317-3 | IEC 60317-20, IEC 60317-4 | IEC 60317-20, IEC 60317-4 | IEC 60317-51, IEC 60317-20 | IEC 60317-23, IEC 60317-3, IEC 60317-8 | IEC60317-13 | IEC60317-26 |

| Tilmaamaha NEMA | NEMA MW 5-C | NEMA MW 5-C | MW 75C | MW 79, MW 2, MW 75 | MW 82, MW79, MW75 | MW 77, MW 5, MW 26 | NEMA MW 35-C | NEMA MW 81-C |

| UL-Ansixinta | / | HAA | HAA | HAA | HAA | HAA | HAA | HAA |

| Dhexroorkala heli karo | 0.03mm-4.00mm | 0.03mm-4.00mm | 0.03mm-4.00mm | 0.03mm-4.00mm | 0.03mm-4.00mm | 0.03mm-4.00mm | 0.03mm-4.00mm | 0.03mm-4.00mm |

| Tuska heerkulka (°C) | 130 | 155 | 155 | 155 | 180 | 180 | 200 | 220 |

| Jilicsan Heerkulka Burburka (°C) | 240 | 270 | 200 | 200 | 230 | 300 | 320 | 350 |

| Heerkulka shoogga kulaylka (°C) | 155 | 175 | 175 | 175 | 200 | 200 | 220 | 240 |

| Lahaanshaha | Aan la alxan karin | Aan la alxan karin | 380 ℃/2s oo la iibin karo | 380 ℃/2s oo la iibin karo | 390 ℃/3s la iibin karo | Aan la alxan karin | Aan la alxan karin | Aan la alxan karin |

| Astaamaha | Iska caabbinta kulaylka wanaagsan iyo xoogga farsamada. | Iska caabin kiimiko oo heer sare ah; iska caabin xoqan oo wanaagsan; caabbinta hydrolysis liidata | Heerkulka burburka jilicsan ayaa ka sarreeya UEW/130; fududahay in la rinjiyeeyo; luminta dielectric hooseeya ee soo noqnoqda sare; biyo milix leh ma jiro | Heerkulka burburka jilicsan ayaa ka sarreeya UEW/130; fududahay in la rinjiyeeyo; luminta dielectric hooseeya ee soo noqnoqda sare; biyo milix leh ma jiro | Heerkulka burburka jilicsan ayaa ka sarreeya UEW/155; heerkulka alxan toos ah waa 390 °C; fududahay in la rinjiyeeyo; luminta dielectric hooseeya ee soo noqnoqda sare; biyo milix leh ma jiro | Iska caabbinta kulaylka sare; iska caabin kiimikaad oo heersare ah, shoog kulayl sare leh, burbur jilicsan oo sarreeya | Iska caabbinta kulaylka sare; xasilloonida kulaylka; qaboojiye qabow u adkaysta; burburka jilicsanaanta sare; shoog kulaylka sare | Iska caabbinta kulaylka sare; xasilloonida kulaylka; qaboojiye qabow u adkaysta; burburka jilicsanaanta sare; kulaylka sareeyo |

| Codsiga | Matoorka caadiga ah, Transformer dhexdhexaad ah | Matoorka caadiga ah, Transformer dhexdhexaad ah | Relays, mishiinada yar yar, Transformers yar yar, gariiradaha dabka shiida, biyaha joogsiga, madax birlabeedka, gariiradaha qalabka isgaarsiinta. | Relays, mishiinada yar yar, Transformers yar yar, gariiradaha dabka shiida, biyaha joogsiga, madax birlabeedka, gariiradaha qalabka isgaarsiinta. | Relays, mishiinada yar yar, Transformers yar yar, gariiradaha dabka shiida, biyaha joogsiga, madax birlabeedka, gariiradaha qalabka isgaarsiinta. | Transformer-ka saliidda lagu shubay, matoor yar, matoor awood sare leh, beddelme heerkul sarreeya, qayb kulaylka u adkaysata | Transformer-ka saliidda lagu shubay, matoor awood sare leh, transformer heerkul sare leh, qayb kulaylka u adkaysata, matoor xidhan | Transformer-ka saliidda lagu shubay, matoor awood sare leh, transformer heerkul sare leh, qayb kulaylka u adkaysata, matoor xidhan |

IEC 60317 (GB/T6109)

Halbeegyada Tiknoolajiyada & Tilmaamaha ee fiilooyinka shirkadeena waxay ku jiraan nidaamka halbeeg caalami ah, oo leh halbeeg millimitir (mm). Haddii aad isticmaasho Qiyaasta Siliga Ameerikaanka (AWG) iyo Biritishka Heerka Wire Gauge (SWG), shaxdan soo socotaa waa miiska isbarbardhigga ee tixraacaada.

Cabbirka ugu gaarka ah ayaa loo habeyn karaa iyadoo loo eegayo shuruudaha macaamiisha.

Isbarbardhigga Farsamada & Tilmaamaha Dhaqdhaqaaqayaasha Biraha ee kala duwan

| BIRTA | Copper | Aluminium Al 99.5 | CCA 10% | CCA 15% | CCA20% |

| Dhexroor la heli karo | 0.03mm-2.50mm | 0.10mm-5.50mm | 0.05mm-8.00mm | 0.05mm-8.00mm | 0.05mm-8.00mm |

| Cufnaanta [g/cm³] Nom | 8.93 | 2.70 | 3.30 | 3.63 | 4.00 |

| Habdhaqanka[S/m * 106] | 58.5 | 35.85 | 36.46 | 37.37 | 39.64 |

| IACS[%] Nom | 101 | 62 | 62 | 65 | 69 |

| Heerkulka-Coefficient[10-6/K] Min - Ugu badnaan | 3800 - 4100 | 3800 - 4200 | 3700 - 4200 | 3700 - 4100 | 3700 - 4100 |

| Kordhinta (1)[%] Nom | 25 | 20 | 15 | 16 | 17 |

| Xoog xajin (1) [N/mm²] Nom | 260 | 110 | 130 | 150 | 160 |

| Nolosha Flex (2)[%] Nom | 100 | 20 | 50 | 80 |

|

| Birta dibadda mug ahaan[%] Nom | - | - | 8-12 | 13-17 | 18-22 |

| Birta dibadda miisaan ahaan[%] Nom | - | - | 28-32 | 36-40 | 47-52 |

| Weldability/Ladnaanta[--] | ++/++ | +/-- | ++/++ | ++/++ | ++/++ |

| Guryaha | Dhaqdhaqaaq aad u sarreeya, xoog cufan oo wanaagsan, dherer sare, dabaysha aad u fiican, alxanka wanaagsan iyo alxanka | Cufnaanta aadka u hooseeya waxay ogolaataa dhimista miisaanka sare, kuleylka degdega ah, dhaqdhaqaaqa hooseeya | CCA waxay isku daraysaa faa'iidooyinka Aluminium iyo Copper. Cufnaanta hoose waxay u oggolaaneysaa dhimista miisaanka, kor u kaca awoodda iyo xoogga xajinta marka la barbar dhigo Aluminium, alxanka wanaagsan iyo alxanka, lagu taliyay dhexroor 0.10mm iyo wixii ka sareeya | CCA waxay isku daraysaa faa'iidooyinka Aluminium iyo Copper. Cufnaanta hoose waxay u oggolaanaysaa dhimista miisaanka, kor u kaca awoodda iyo xoogga xajinta marka la barbar dhigo aluminium, alxanka wanaagsan iyo alxanka, lagu taliyay cabbir aad u fiican ilaa 0.10mm | CCA waxay isku daraysaa faa'iidooyinka Aluminium iyo Copper. Cufnaanta hoose waxay u oggolaanaysaa dhimista miisaanka, kor u kaca awoodda iyo xoogga xajinta marka la barbar dhigo aluminium, alxanka wanaagsan iyo alxanka, lagu taliyay cabbir aad u fiican ilaa 0.10mm |

| Codsiga | Dabaysha gariiradda guud ee codsiga korantada, silig HF litz. Si loogu isticmaalo warshadaha, baabuurta, qalabka, elektiroonigga macaamiisha | Codsi koronto oo kala duwan oo leh shuruudo miisaan yar, silig HF litz. Si loogu isticmaalo warshadaha, baabuurta, qalabka, elektiroonigga macaamiisha | Sameecad-sheege, taleefoonka dhegaha iyo dhegaha, HDD, kuleyliyaha kicinta oo u baahan joojinta wanaagsan | Sameecad-qaade, taleefoonka dhegaha iyo dhegaha, HDD, kuleyliyaha kicinta ee baahida joojinta wanaagsan, fiilada HF litz | Sameecad-qaade, taleefoonka dhegaha iyo dhegaha, HDD, kuleyliyaha kicinta ee baahida joojinta wanaagsan, fiilada HF litz |

Tilmaamaha siliga aluminium ee naxaas ah ee naxaas ah

| Dhexroorka magacaaban | Dulqaadka maamulaha | G1 | G2 | Korontada jabinta ugu yar (V) | Kordhinta ugu yar | |||

| Dhumucda filimka ugu yar | Dhexroorka ugu sarreeya oo dhammaystiran (mm) | Dhumucda filimka ugu yar | Dhexroorka ugu sarreeya oo dhammaystiran (mm) | G1 | G2 | |||

| 0.10 | 0.003 | 0.005 | 0.115 | 0.009 | 0.124 | 1200 | 2200 | 11 |

| 0.12 | 0.003 | 0.006 | 0.137 | 0.01 | 0.146 | 1600 | 2900 | 11 |

| 0.15 | 0.003 | 0.0065 | 0.17 | 0.0115 | 0.181 | 1800 | 3200 | 15 |

| 0.17 | 0.003 | 0.007 | 0.193 | 0.0125 | 0.204 | 1800 | 3300 | 15 |

| 0.19 | 0.003 | 0.008 | 0.215 | 0.0135 | 0.227 | 1900kii | 3500 | 15 |

| 0.2 | 0.003 | 0.008 | 0.225 | 0.0135 | 0.238 | 2000 | 3600 | 15 |

| 0.21 | 0.003 | 0.008 | 0.237 | 0.014 | 0.25 | 2000 | 3700 | 15 |

| 0.23 | 0.003 | 0.009 | 0.257 | 0.016 | 0.271 | 2100 | 3800 | 15 |

| 0.25 | 0.004 | 0.009 | 0.28 | 0.016 | 0.296 | 2300 | 4000 | 15 |

| 0.27 | 0.004 | 0.009 | 0.3 | 0.0165 | 0.318 | 2300 | 4000 | 15 |

| 0.28 | 0.004 | 0.009 | 0.31 | 0.0165 | 0.328 | 2400 | 4100 | 15 |

| 0.30 | 0.004 | 0.01 | 0.332 | 0.0175 | 0.35 | 2400 | 4100 | 16 |

| 0.32 | 0.004 | 0.01 | 0.355 | 0.0185 | 0.371 | 2400 | 4200 | 16 |

| 0.33 | 0.004 | 0.01 | 0.365 | 0.019 | 0.381 | 2500 | 4300 | 16 |

| 0.35 | 0.004 | 0.01 | 0.385 | 0.019 | 0.401 | 2600 | 4400 | 16 |

| 0.37 | 0.004 | 0.011 | 0.407 | 0.02 | 0.425 | 2600 | 4400 | 17 |

| 0.38 | 0.004 | 0.011 | 0.417 | 0.02 | 0.435 | 2700 | 4400 | 17 |

| 0.40 | 0.005 | 0.0115 | 0.437 | 0.02 | 0.455 | 2800 | 4500 | 17 |

| 0.45 | 0.005 | 0.0115 | 0.488 | 0.021 | 0.507 | 2800 | 4500 | 17 |

| 0.50 | 0.005 | 0.0125 | 0.54 | 0.0225 | 0.559 | 3000 | 4600 | 19 |

| 0.55 | 0.005 | 0.0125 | 0.59 | 0.0235 | 0.617 | 3000 | 4700 | 19 |

| 0.57 | 0.005 | 0.013 | 0.61 | 0.024 | 0.637 | 3000 | 4800 | 19 |

| 0.60 | 0.006 | 0.0135 | 0.642 | 0.025 | 0.669 | 3100 | 4900 | 20 |

| 0.65 | 0.006 | 0.014 | 0.692 | 0.0265 | 0.723 | 3100 | 4900 | 20 |

| 0.70 | 0.007 | 0.015 | 0.745 | 0.0265 | 0.775 | 3100 | 5000 | 20 |

| 0.75 | 0.007 | 0.015 | 0.796 | 0.028 | 0.829 | 3100 | 5000 | 20 |

| 0.80 | 0.008 | 0.015 | 0.849 | 0.03 | 0.881 | 3200 | 5000 | 20 |

| 0.85 | 0.008 | 0.016 | 0.902 | 0.03 | 0.933 | 3200 | 5100 | 20 |

| 0.90 | 0.009 | 0.016 | 0.954 | 0.03 | 0.985 | 3300 | 5200 | 20 |

| 0.95 | 0.009 | 0.017 | 1.006 | 0.0315 | 1.037 | 3400 | 5200 | 20 |

| 1.0 | 0.01 | 0.0175 | 1.06 | 0.0315 | 1.094 | 3500 | 5200 | 20 |

| 1.05 | 0.01 | 0.0175 | 1.111 | 0.032 | 1.145 | 3500 | 5200 | 20 |

| 1.1 | 0.01 | 0.0175 | 1.162 | 0.0325 | 1.196 | 3500 | 5200 | 20 |

| 1.2 | 0.012 | 0.0175 | 1.264 | 0.0335 | 1.298 | 3500 | 5200 | 20 |

| 1.3 | 0.012 | 0.018 | 1.365 | 0.034 | 1.4 | 3500 | 5200 | 20 |

| 1.4 | 0.015 | 0.018 | 1.465 | 0.0345 | 1.5 | 3500 | 5200 | 20 |

| 1.48 | 0.015 | 0.019 | 1.546 | 0.0355 | 1.585 | 3500 | 5200 | 20 |

| 1.5 | 0.015 | 0.019 | 1.566 | 0.0355 | 1.605 | 3500 | 5200 | 20 |

| 1.6 | 0.015 | 0.019 | 1.666 | 0.0355 | 1.705 | 3500 | 5200 | 20 |

| 1.7 | 0.018 | 0.02 | 1.768 | 0.0365 | 1.808 | 3500 | 5200 | 20 |

| 1.8 | 0.018 | 0.02 | 1.868 | 0.0365 | 1.908 | 3500 | 5200 | 20 |

| 1.9 | 0.018 | 0.021 | 1.97 | 0.0375 | 2.011 | 3500 | 5200 | 20 |

| 2.0 | 0.02 | 0.021 | 2.07 | 0.04 | 2.113 | 3500 | 5200 | 20 |

| 2.5 | 0.025 | 0.0225 | 2.575 | 0.0425 | 2.62 | 3500 | 5200 | 20 |

Isbarbardhigga xiisadda badbaadada ee hawlgalka dabaysha siliga (oo la magac baxay fiilooyinka aluminium-ka daboolan ee wareegsan)

| Dhexroorka maamulaha (mm) | Xiisad (g) | Dhexroorka maamulaha (mm) | Xiisad (g) |

| 0.1 | 49 | 0.45 | 501 |

| 0.11 | 59 | 0.47 | 497 |

| 0.12 | 70 | 0.50 | 563 |

| 0.13 | 79 | 0.51 | 616 |

| 0.14 | 85 | 0.52 | 608 |

| 0.15 | 97 | 0.53 | 632 |

| 0.16 | 111 | 0.55 | 545 |

| 0.17 | 125 | 0.60 | 648 |

| 0.18 | 125 | 0.65 | 761 |

| 0.19 | 139 | 0.70 | 882 |

| 0.2 | 136 | 0.75 | 1013 |

| 0.21 | 150 | 0.80 | 1152 |

| 0.22 | 157 | 0.85 | 1301 |

| 0.23 | 172 | 0.90 | 1458 |

| 0.24 | 187 | 0.95 | 1421 |

| 0.25 | 203 | 1.00 | 1575 |

| 0.26 | 220 | 1.05 | 1736 |

| 0.27 | 237 | 1.10 | 1906dii |

| 0.28 | 255 | 1.15 | 2083 |

| 0.29 | 273 | 1.20 | 2268 |

| 0.3 | 251 | 1.25 | 2461 |

| 0.32 | 286 | 1.30 | 2662 |

Fiiro gaar ah: Had iyo jeer isticmaal dhammaan hababka badbaadada ugu fiican oo fiiro gaar ah u yeelo tilmaamaha badbaadada ee winder-ka ama soo saaraha qalabka kale.

Ka taxadarida isticmaalka OGAYSIIS ISTICMAALKA