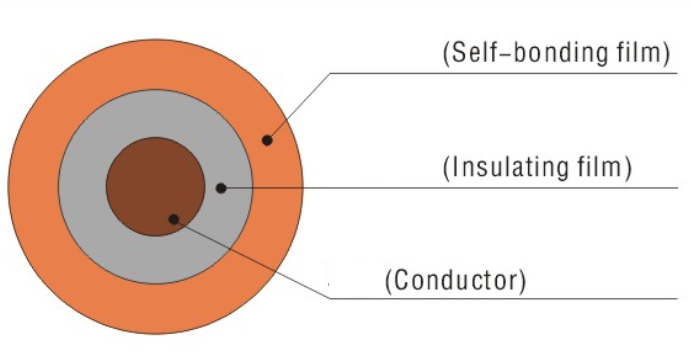

Tanda mai ɗaure kai

Kayan da aka yi da kai na tanda yana samun sakamako mai mannewa ta hanyar sanya kwandon da aka gama a cikin tanda don dumama. Domin cimma daidaitaccen dumama na'urar, dangane da siffa da girman coil ɗin, yawan zafin jiki na tanda yana buƙatar kasancewa tsakanin 120 ° C da 220 ° C, kuma lokacin da ake buƙata shine minti 5 zuwa 30. Tanda mai ɗaure kai na iya zama rashin daidaituwa ga wasu aikace-aikace saboda dogon lokacin da ake buƙata.

| Amfani | Hasara | Hadarin |

| 1. Ya dace da maganin zafi bayan yin burodi 2. Dace da multilayer coils | 1. tsadar tsada 2. dogon lokaci | gurbacewar kayan aiki |

Sanarwa na Amfani

1. Da fatan za a koma zuwa taƙaitaccen samfurin don zaɓar samfurin samfurin da ya dace da ƙayyadaddun bayanai don guje wa rashin amfani saboda rashin daidaituwa.

2. Lokacin karɓar kaya, tabbatar da ko akwatin marufi na waje ya murƙushe, ya lalace, ya lalace ko ya lalace; yayin sarrafa, yakamata a kula dashi a hankali don gujewa girgiza kuma an saukar da duka kebul ɗin.

3. Kula da kariya yayin ajiya don hana lalacewa ko murkushe ta da abubuwa masu wuya kamar karfe. An haramta hadawa da adanawa tare da kaushi na halitta, acid mai karfi ko alkalis mai karfi. Idan ba a yi amfani da samfuran ba, zaren zaren ya kamata a tattara su sosai kuma a adana su a cikin marufi na asali.

4. Ya kamata a adana wayan da aka sanya a cikin ma'ajiyar iska mai nisa daga ƙura (ciki har da ƙurar ƙarfe). An haramta ba da kai tsaye hasken rana da kuma guje wa yawan zafin jiki da zafi. Mafi kyawun yanayin ajiya shine: zazzabi ≤ 30 ° C, dangi zafi & 70%.

5. Lokacin cire bobbin enameled, yatsan hannun dama da yatsa na tsakiya suna haɗa ramin farantin ƙarshen ƙarshen reel, kuma hannun hagu yana goyan bayan farantin ƙarshen ƙarshen. Kada ka taɓa wayar enameled kai tsaye da hannunka.

6. Yayin da ake yin iska, sanya bobbin a cikin murfin biya kamar yadda zai yiwu don kauce wa gurɓataccen ƙwayar waya. A cikin aiwatar da sanya waya, daidaita tashin hankali na iska daidai da ma'aunin tashin hankali don guje wa karyewar waya ko tsayin waya saboda tashin hankali da ya wuce kima. Da sauran batutuwa. A lokaci guda kuma, an hana wayar daga haɗuwa da abu mai wuya, wanda ya haifar da lalacewa ga fim din fenti da gajeren kewayawa.

7. Warware-m kai m waya bonding ya kamata kula da taro da adadin ƙarfi (methanol da cikakken ethanol ana shawarar). A lokacin da ake haɗa waya mai ɗaukar zafi mai narkewa mai zafi, kula da nisa tsakanin bindigar zafi da ƙirar da daidaita yanayin zafi.